With the maturing of telecom industry, competitiveness and social responsibility are becoming more and more important and energy savings and CO2 emission reduction solutions become a hot topic. Meanwhile, the continuous increase in fuel costs for generators is driving operators who are using power in off-grid or unreliable-grid locations to search for more cost-effective ways to power their operations. Therefore, choosing a reliable and optimized power supply system is vital for staying competitive. Choosing an suboptimal hybrid technology may have a major impact on the site’s operating costs and increase the CO2 emissions unnecessarily.

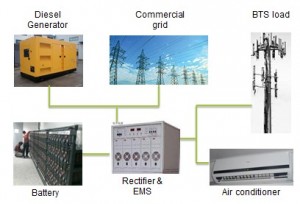

In an optimally balanced hybrid power system many things should be considered. Below is an illustration of an integrated system consisting of Diesel Gen set, diesel fuel tank, energy storage battery, air conditioner, thermal management system and system controller

.

1. Battery discharge performance

Battery cycle life and total capacity output vs. DOD% and temperature

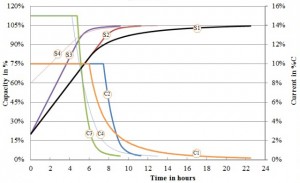

2. Battery fast recharge performance

Charge performance difference under different charge performance

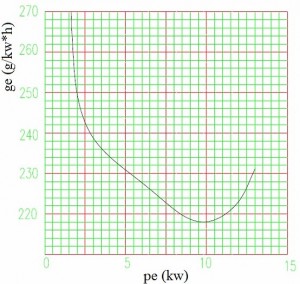

3. Diesel consumption of Gen set

Diesel consumption vs. power output

4. Diesel efficiency

To gain more power from DG and save operation expenses at the same time, there are two major points to be considered, one is to reduce DG operation time, another is to keep DG output in the best range.

Diesel consumption during recharge without A/C on

5. DG/Battery Hybrid Applications

DG/Battery Hybrid –Power cube

DG/Battery hybrid site I

DG/Battery hybrid site II